DiloGroup

DiloGroup

DiloGroup

DiloGroup

DiloGroup

The automotive nonwovens sector represents one of the most dynamic applications of nonwoven technology, with contemporary vehicles incorporating over 40 distinct components manufactured from specialized needlefelt materials. These engineered automotive textiles deliver exceptional value through their low-density characteristics and strategic incorporation of recycled natural fibers, enabling the production of environmentally sustainable components with significant weight reduction benefits.

The emergence of electric mobility platforms has dramatically increased demand for lightweight automotive materials, as vehicle manufacturers seek to extend battery range through comprehensive vehicle weight optimization. Nonwoven components offer compelling advantages in this context, providing substantial weight savings compared to conventional automotive materials while maintaining critical performance specifications.

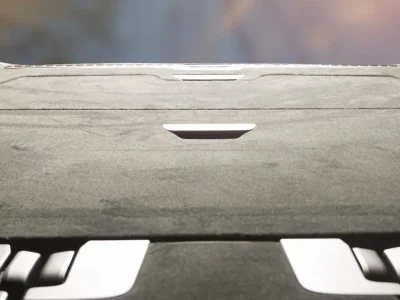

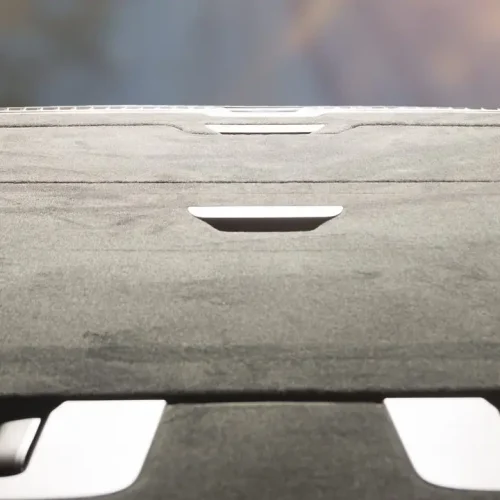

Within automotive interior applications, manufacturers utilize both flat needlefelt constructions and velour-textured needlefelts for interior lining components. These specialized automotive textiles must satisfy rigorous performance requirements, particularly regarding abrasion resistance standards and surface uniformity specifications to ensure long-term durability and premium aesthetic quality throughout the vehicle lifecycle.

DiloGroup is a top machinery manufacturer, specializing in complete nonwoven production lines and fiber processing equipment. Their solutions allow for the creation of custom nonwoven materials with specific properties like filtration efficiency and sound absorption. They serve diverse markets, including automotive, construction, and filtration.These modular systems can be integrated to meet educational and technical needs, offering efficient processing for research applications. The series includes lab-scale extruders, calenders, and testing apparatus, serving as a vital resource for polymer science.Whether for polymer processing demonstrations or material development, the Teach Line system supports both theory and practice in a user-friendly format.

DiloGroup

DiloGroup

Indonesia Representative Office

Sahid Sudirman Center, Suite C, 42nd Floor, JI. Jendral Sudirman No Kav 86, Karet Tengsin, Tanah Abang, Jakarta Pusat 10220, Indonesia

Malaysia Central Region Office

D11-11-G & D11-11-1,

Pusat Perdagangan Dana 1,

Jalan PJU 1A/46,

47301 Petaling Jaya, Selangor

Malaysia

Malaysia Nothern Region Office

Prima Tanjung, Jalan Fettes, Tanjung Tokong, 11200, Penang, Malaysia

Singapore Office

25 International Business Park, #04-103D German Centre, Singapore 609916

2026 Copyright © Ant Spirits PTE LTD (202332416D)